Projects

UELS has extensive experience in designing various types of pits, from small reserve pits to

large-scale one million barrel projects. With a skilled and experienced staff, we are equipped to

assist our clients throughout the entirety of their projects, from surveying and design to

permitting, construction, inspection, and reclamation.

UELS has extensive experience in bore design, ranging from minor projects like a county road

crossing to notable examples such as the longest Horizontal Directional Drilling (HDD) bore in

the world, completed under Lake Sakakawea in North Dakota by our client, Kinder Morgan.

UELS was intricately involved in this groundbreaking project, which spanned over a three-year

period. Initially, UELS surveyed the preliminary route for the project, collecting profile data,

including data on the lake bed, using sonar technology from a boat and GPS devices to

calculate the elevation of the lake bed. This crucial profile data formed the foundation of the

HDD design. Additionally, UELS played a pivotal role in positioning barges for soil testing bores

conducted beneath the lake's surface. Throughout the construction phase, UELS meticulously

gathered survey data on each weld and pipe prior to the pullback process. This meticulous

approach enabled us to maintain a comprehensive inventory and precise location of every

element of the pipeline, including the segment situated under the lake. UELS was a deeply

involved and integral part of the success of this monumental project.

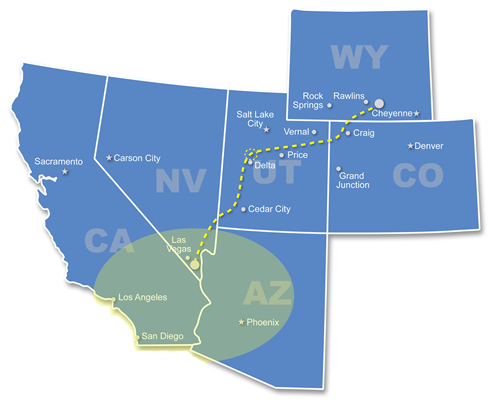

UELS provided surveying, right-of-way and mapping services for a powerline project involving 700+ miles

of right-of-way running from near Rawlins, Wyoming to Las Vegas, Nevada. Our services included

establishing a survey grid, control point monument records, powerline and access road right-of-way

plats for each land owner and GIS services.

Pike Solar Project

UELS provided construction staking services for the Pike Solar 223.6 MW Project that covered roughly 1,236 acres. The client needed us to stake 87,990 support pile locations for the infrastructure of the solar panels at a rate of 500 per day to stay ahead of the pile installation crews. In addition to the support piles, we also were tasked with staking the perimeter fence and gates. UELS prides itself in providing accurate and timely construction staking that meets or exceeds the client

demands.

Fairview Fire Station

Fairview, Montana

UELS teamed with Stevenson Design, Inc. to design and construct a fire station and senior center in Fairview, Montana for Richland County. The building is a pre-engineered metal building that houses (3) three pull-thru apparatus bays, (1) one work bay, (1) one wash bay, and a (2) two bay vehicle storage garage. In addition to the fire station, a Senior Center is attached to the south side of the building, which includes a Dining Areas, Full Kitchen, Office, and Restrooms. The building services the community of Fairview in Richland County, Montana.

UELS performed the initial site survey and worked closely with the Architect and County personnel to layout the site to maximize parking and access in and out of the building. The parking areas and driveway approaches are all concrete pavement. This site required relocation of a communications antennae and flagpole. UELS prepared site grading plans and utility plans for construction of the site work.

In addition to the Civil Site Engineering, UELS prepared structural engineering drawings for the steel building, foundation, and mezzanine structure for the fire station and senior center areas of the buildings. The site included previously placed fill, encountered during the Geotech investigation that required excavation and replacement.

UELS provided engineering support during construction of the facility and construction staking of the facility.

BAGHOUSE STRUCTURAL PROJECT

American Gilsonite Company planned to install a new Baghouse bin in their processing tower at their Bonanza Mine Facility. The Baghouse would be installed in the 3rd level of their loading tower. The new Baghouse weighs approximately 54,000 lbs when full of gilsonite ore.

UELS was responsible for the structural engineering of the project to support the new Baghouse. This required that the majority of the beams, girders, and columns supporting the third level deck be retrofitted to increase the capacity of the supporting structure. UELS used structural analysis software to calculate the load and design the steel retrofit sections. The columns were retrofit with steel plate that was stitch welded to the flanges of the wide flange steel section to increase their capacity. Detailed construction plans were prepared that depicted the retrofit welding and construction procedures to install the retrofit sections.

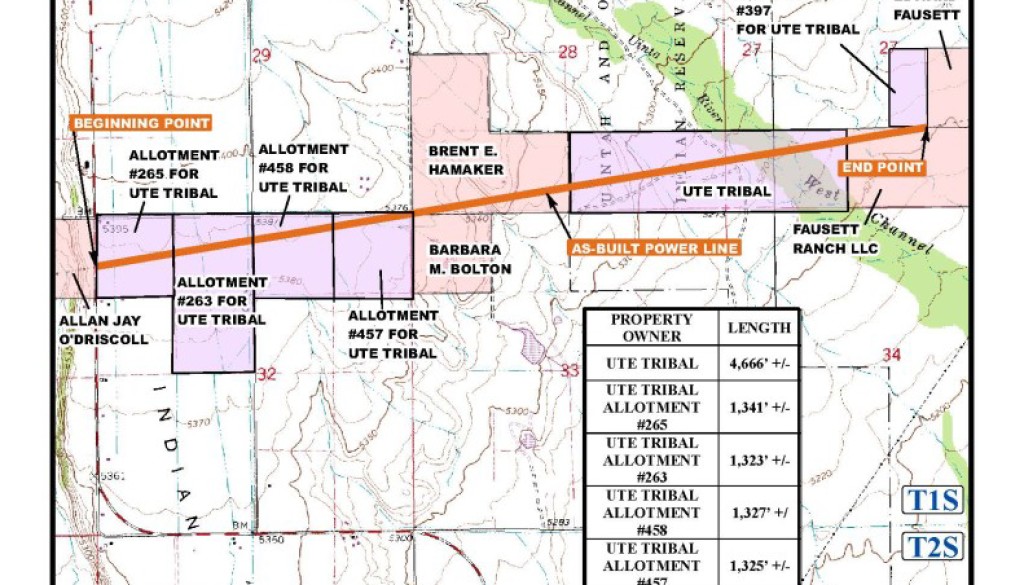

138 KV CARBON TO ASHLEY TRANSMISSION LINE

UELS provided land surveying and drafting services for Rocky Mountain Power’s 138 kV Carbon to Ashley Transmission Line project. The project entailed monitoring construction survey control and performing as-built survey on approximately 14,000 feet of 138kV High-Voltage Transmission Line.

In addition to the survey services, our drafting team prepared As-Built right of way plats for the portion of the line that crosses Tribal Lands. Our ROW plats are of the highest quality and we are continually praised for the clear concise detailing of our survey plats.

UELS prides itself on the quality of our survey work for long transmission projects. One of the challenges to these projects is carrying accurate survey control for the entire length of the project, and for this project Rocky Mountain Power was extremely satisfied with our work.

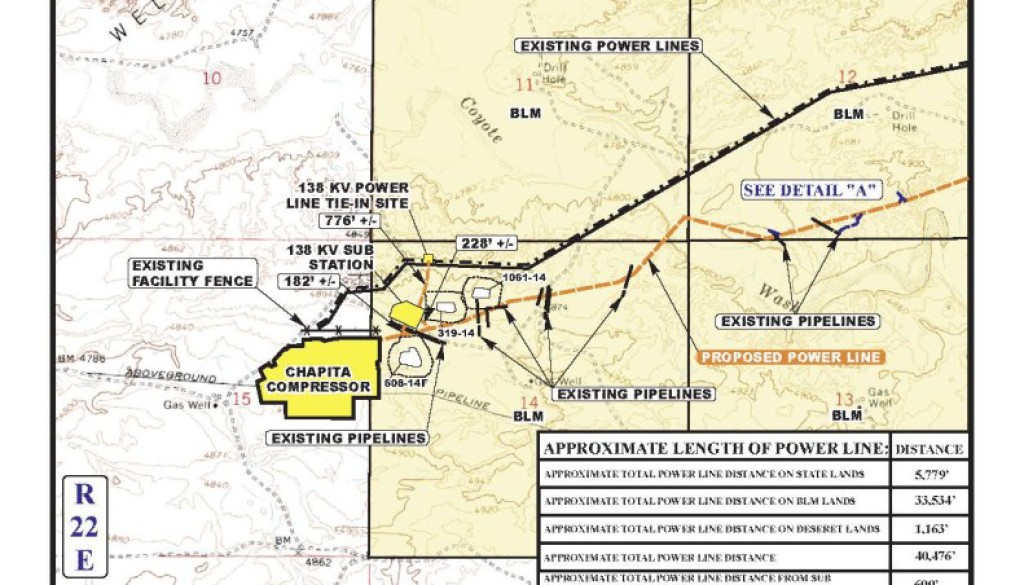

138 KV POWERPLANT TO CHIPETA COMPRESSOR

UELS provided Land Surveying, Civil Engineering, and Drafting services for Anadarko Uintah Midstream, LLC’s 138 kV Powerplant to Chipeta Compressor Station Transmission Line project. The project entailed monitoring construction survey control and performing as-built survey on approximately 8 miles of 138kV High-Voltage Transmission Line.

In addition to the survey services, our engineering and drafting team prepared right of way plats for the portion of the line that crosses Utah State Trust Lands (SITLA), topo maps of the proposed line alignment, and site grading plans for the tie-in substation at the Chipeta Compressor Station. Our ROW plats and construction plans are of the highest quality and we are continually praised for the clear concise detailing of our survey plats.

UELS prides itself on the quality of our survey work for long transmission projects. One of the challenges to these projects is carrying accurate survey control for the entire length of the project, and for this project Anadarko Uintah Midstream, LLC was extremely satisfied with our work.

1ST AVENUE SEWER LINE

Daggett County, in its efforts to sell building lots along 1st Avenue and South Boulevard in Dutch John, needed to provide sewer service to the lots. UELS designed and prepared construction documents for the installation of 530 feet of Sewer Line to service 5 lots. UELS was provide Construction Engineering Management, Construction Surveying, and Construction Inspection during the installation of the line.

PIPELINE SUSPENSION BRIDGE

Anadarko Petroleum Corporation installed an extensive natural gas gathering system in the Natural Buttes Gas Field in Uintah County, Utah. The gathering pipelines were routed and planned to cross a 100’ gulch to eliminate the cost of running the alignment to the head of the drainage and back. A suspension bridge design was chosen as the desired structural support system for the pipeline bridge. Three pipelines were planned to cross the gulch. The design required that all of the installation work be accomplished from the banks of the gulch. The pipe saddles consisted of pipe rollers that allowed the pipelines to be rolled across the supports for the final installation of the pipe casings. The bridge consisted of two A-frame supports at each bank, two 2” suspension cables, (4) concrete deadman foundation anchors, pipe support frames, and a 1” wind stay cable. The final span was 120’, due to the location of the frames on the banks. UELS prepared complete construction documents, materials order lists, and performed construction inspection.

BROSS WELL PAD – FORT BERTHOLD

HRC Resources, LLC had a challenging well pad, with difficult construction constraints. Our survey crews out of North Dakota and Montana surveyed the location using GPS Survey equipment. The well location was constrained by disturbance limits on all four boundaries of the pad. UELS used an AutoCAD Civil 3D grading model to prepare multi-phase construction options to aid in the construction cost of the well pad. Due to the boundary constraints, retaining walls would be required in order to keep the working space needed on the well pad so that the slope of the pad would not extend past boundary limit. UELS coordinated with the geotechnical firm Braun Intertech to work through the design of retaining wall heights and locations. The grading model information was passed on to Braun Intertech to design the retaining wall systems. The slope locations required a top down and a bottom up pile and lagging system. The top down system was used to construct a cut slope wall that was required to maintain a vegetated buffer between the uphill edge of the pad and a nearby highway. The bottom up system was used on the downhill slopes to retain the soil from the fill side of the well pad. UELS worked closely with the contractor in providing construction survey staking of the locations of the retaining wall piles. In addition to the civil grading, UELS prepared right-of-way and alignment plats for the access road and pipelines to service the well location and our typical well plat package; which contains, bottom hole and surface hole legal plats, production layouts, reclamation layouts, and a SWPPP plan.

AMBROSE TOWNSHIP 108TH STREET NW PROPOSED ROAD CONSTRUCTION & IMPROVEMENTS

Samson Resource Company operates multiple oil and gas well locations along 108th Street NW in the Ambrose Township of North Dakota. The road was originally constructed as a farm access road along the section line, but with the increased year-round travel of large and heavy commercial traffic, the road was in need of improvements. Along with the proposed improvements, Samson also desired to extend the existing 5 mile segment of road with an additional 1/2 mile on the West end and 1 mile on the East end, to tie into other existing Samson well locations.

UELS provided all of the preliminary surveying data collection along the 6.5 mile project. UELS also coordinated geotechnical investigation and engineering services, along with assisting with the environmental consultation for wetland delineation. UELS then prepared permitting construction documents for county road approaches, NDDOT highway accesses, and a full design plan set, including plan and profile sheets and cross-sections. Also included in the design plan set were earthwork quantities, imported material requirements, geotechnical improvements, including design of subgrade and stabilization for heavy truck traffic, restriction on wetlands and culvert extensions/replacements, and other various grading and drainage improvements. UELS provided engineer’s estimates and bidding assistance to Samson during the final project scoping and construction bidding.

CHAPITA COMPRESSOR STATION – TRAINS 3 & 4

Anadarko Petroleum Corporation designed and constructed Train 3 and 4 of the Chapita Compressor station, in Uintah County, Utah, in 2010 and 2011. These two trains were part of a 51 Acre development. UELS provided Surveying and Civil Engineering design and construction services. The new train required drainage channels, concrete drainage dips, and retention ponds to manage the storm water across the plant site. An MSE wall was used in the Pond #1 area to allow for the required retention volume and not cut off access to the Train 1 area. The storm water system included valving and outlet structures, since the retention ponds also included the site’s secondary containment. UELS prepared construction documents for the site grading and provided construction staking services during the construction of the site development for Train 3 and 4.

LEGION TERMINALS, LLC – RIGHT TURN LANE

Uintah Engineering and Land Surveying (UELS) provided Surveying, Design Engineering, Construction Surveying, and Project Management/Inspection services for Legion Terminals, LLC on this project. The project consisted of designing and constructing a right turn lane on North Dakota State Highway 73 for access to the Legion Terminals, LLC Veeder Oil Gathering and Storage Site. UELS was responsible for the design engineering, construction plan preparation, bid document preparation, bid support, bid compilation, NDDOT coordination, construction staking, and construction inspection to meet NDDOT specifications.

The new turn lane will allow for safer deceleration of heavy truck traffic into the site and reduce the slowing of traffic on Highway 73. The site is anticipated to see 24 hour oil haulers arriving at 15-20 minute intervals.

LEGION TERMINALS, LLC – VEEDER TANK SITE

Uintah Engineering and Land Surveying (UELS) worked with Legion Terminals in surveying the 50 acre project site and locating the existing oil and water pipelines crossing the site. Eight 250,000 Bbl crude oil tanks were planned to be constructed on this site, in addition to a truck unloading/loading terminal. Upon completion of the survey, our engineering department worked with a geotechnical firm to perform the site soil borings to prepare a soils report to provide recommendations for the engineering of the site grading and surfacing, tank foundations, on-site retention pit. UELS prepared multiple site grading layouts and provided earthwork estimates to determine the most efficient layout of the site. One of the challenges of this site was that there was a drainage that passed through the middle of the site. The grading plan was prepared in such a way to route the drainage around the tank site and prepare storm water pollution prevention plans (SWPPP) for mitigating the potential for erosion in this bare earth channel.

Upon the completion of a preliminary design of the tank foundations, the tanks would need to be constructed on piles, which would end up driving up the cost of the foundation for multiple tanks. Additional soil borings were performed to determine the ideal location of the tanks to minimize the number of tanks requiring pile foundations.

UELS provided construction inspection and surveying during the construction of the facility earthwork and surfacing.

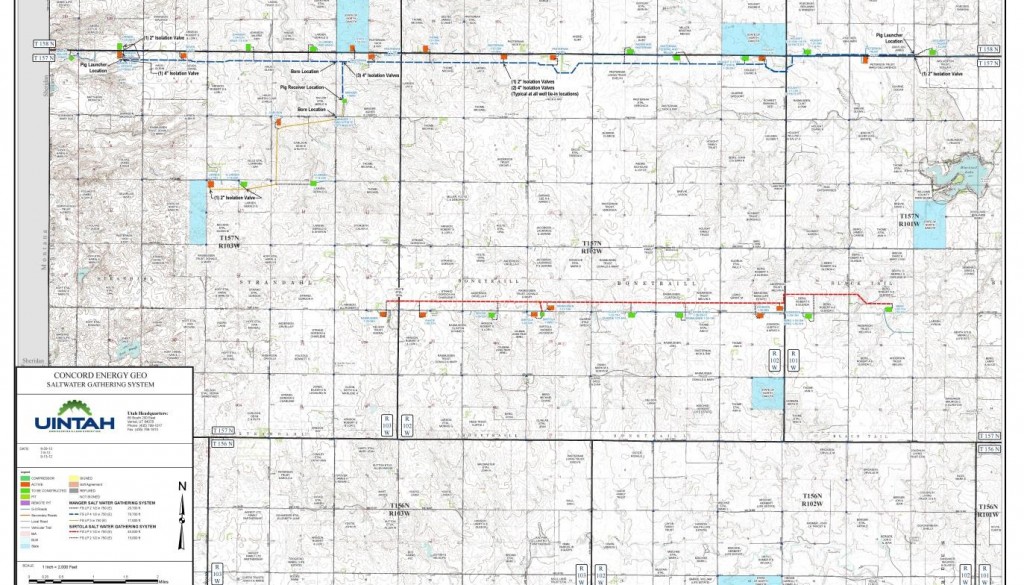

MANAGER AND SIIRTOLA PRODUCED WATER SYSTEM

Uintah Engineering and Land Surveying (UELS) provided Civil Engineering services for Concord Field Services on this project. The project consisted of modeling a Produced Water Gathering System, using WaterCAD software, to determine pump sizes, line sizes, maximum flows and weekly energy costs. The model was created using information from our extensive survey database for determining elevations and well pad locations. UELS modeled several different scenarios and analyzed the results from each scenario in order to develop the most efficient system. UELS provided a detailed Design Engineering Report to Concord Field Services showing the results from the model and prepared an overall system GIS Map. The report provided Concord Field Services with the necessary information regarding pump design, maximum flow, maximum pump TDH, maximum pump pressure set point, pump run time per week, and energy costs per week.

PHOSPHATE FLOTATION CIRCUIT

Simplot Phosphates, at their Vernal Mine Mill Building had undertaken a project to install a flotation circuit to separate the fine phosphate ore from the tailings stream. The flotation circuit was to be installed on the third level deck of 80’ tall New Concentrator building. The flotation circuit equipment, tanks, piping and structure was estimated to weigh over 1 million pounds.

UELS was responsible for the structural engineering of the project to support the flotation circuit. This required that the majority of the beams, girders, and columns supporting the third level deck be retrofitted to increase the capacity of the supporting structure. UELS used structural analysis software to calculate the load and design the steel retrofit sections. Detailed construction plans were prepared that depicted the retrofit welding and construction procedures to install the retrofit sections.

MCJUNKIN RED MAN CORPORATION BUILDING

Arnie Eksund built a 120’ X 60’ metal building. The building is a mixed use warehouse and office space for rental purposes. UELS prepared construction documents for the 2nd story remodel from a mezzanine to office space. Later, the building was rented to McJunkin Redman Corporation, who requested that Mr. Eksund construct a 100’x60’ addition to add 6,000 sf to the existing warehouse space. UELS provided Architectural, Civil Engineering, and Structural Engineering services for the building.

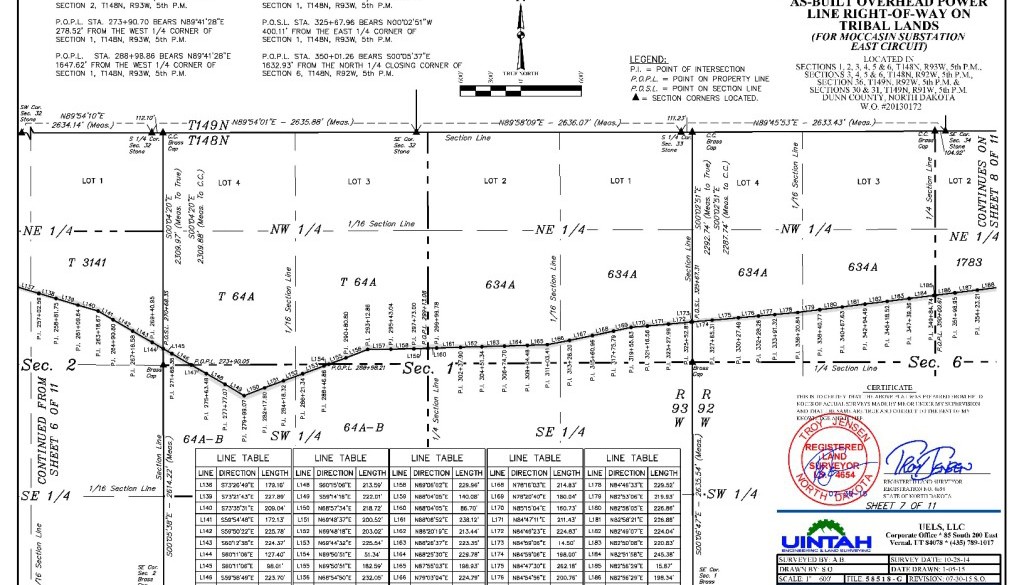

MOCCASIN SUBSTATION EAST CIRCUIT

UELS provided Land Surveying and Drafting services for McKenzie Electric Cooperative’s Moccasin Substation East Circuit Transmission Line project. The project entailed gathering existing topographical and utility survey data, monitoring construction survey control and performing as-built survey on approximately 12 miles of High-Voltage Transmission Line.

In addition to the survey services, our drafting team prepared right of way plats for the entire alignment, shape files of the final alignment, and asbuilt alignment plans. Our ROW plats and construction plans are of the highest quality and we are continually praised for the clear concise detailing of our survey plats.

UELS prides itself on the quality of our survey work for long transmission projects. One of the challenges to these projects is carrying accurate survey control for the entire length of the project, and for this project McKenzie Electric Cooperative was extremely satisfied with our work.

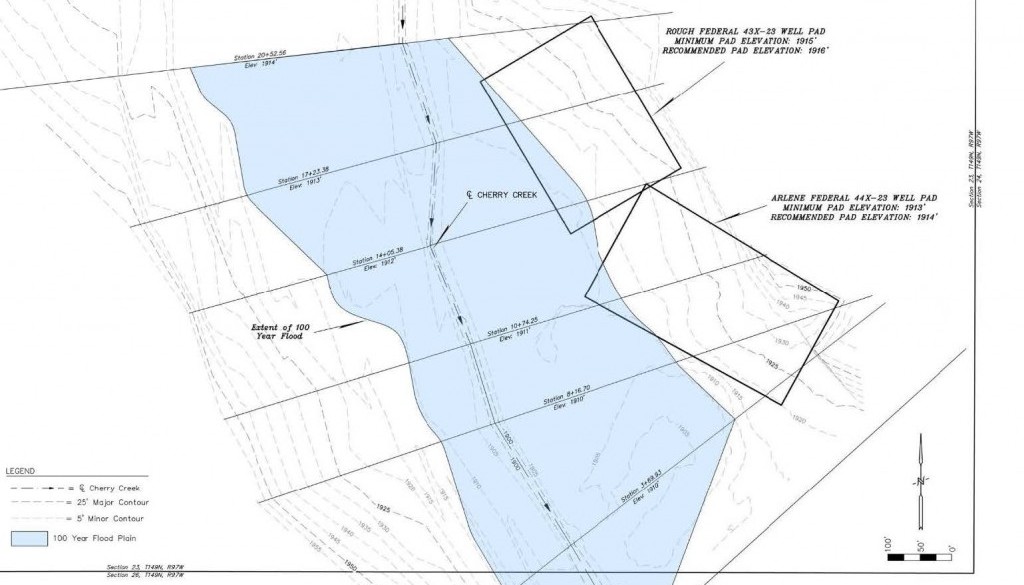

XTO ENERGY, INC – FLOOD PLAIN STUDY

XTO Energy, Inc. proposed to build two well pads, Arlene & Rough Federal, which would lie near an existing flood plain. UELS prepared a flood plain study for the existing watershed analyzing flow depth and velocity. This information was then used to design both well pads to the correct elevation in order to stay above the 100 year flood plain and also provide fill slope protection on the edges of the pad that would be affected by the larger storm. UELS provided Surveying, Civil Engineering and Hydrology Engineering services.

XTO ENERGY SIDNEY, MT FACILITY

XTO Energy, Inc. planned to construct an office and yard facility in Sidney, MT, in order to centralize operations in that area. The facility included a 19,000 SF office building, 5,200 SF shop building, and 1,500 SF cold storage building. In addition to the buildings, the site would include a 27 acre pipe storage yard. UELS prepared civil grading plans for the entire site. UELS coordinated the design of a mound septic system to serve the new buildings. UELS was responsible for obtaining the Montana Department of Transportation Access permit.

In addition to the site grading plans, UELS prepared structural engineering drawings for the pre-engineered metal buildings for the office, shop, and cold storage buildings.

UELS provided engineering support during construction of the facility and construction staking of the facility.